Xa iqondo lokushisa liphezulu kwaye imvula iqhubeka, ayiyi kuba nempembelelo ethile kuphela kwimveliso yefektri yethu, kodwa abathengi abaninzi nabo banenkxalabo enkulu malunga nokugcinwa kwe-sealants.

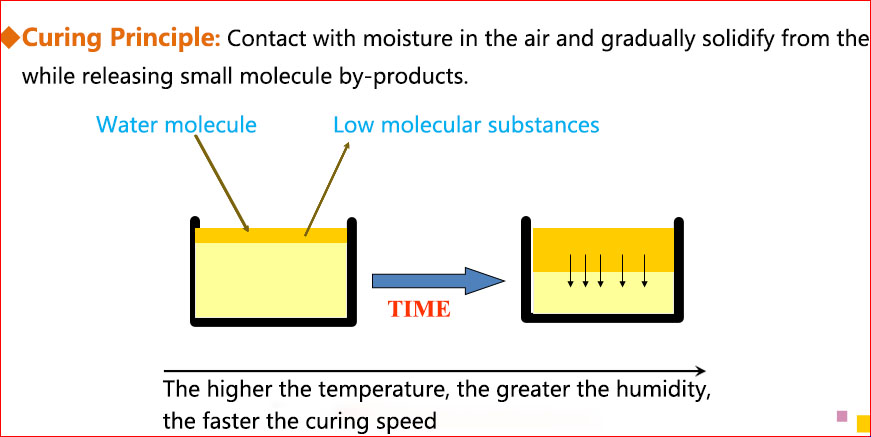

I-Silicone sealant yirabha ye-silicone yobushushu begumbi.Yintlama eyenziwe ngerabha ye-silicone ye-107 kunye ne-filler njengeyona nto iphambili ekrwada, eyongezwa yi-agent ye-crosslinking, i-agent ye-thixotropic, i-agent yokudibanisa, kunye ne-catalyst kwisimo se-vacuum.Isabelana namanzi emoyeni kwaye iqine yenze irabha elastiki abicah.

Iimveliso ze-silicone sealant zineemfuno eziqinileyo kwindawo yokugcina.Indawo yokugcina engafanelekanga iya kunciphisa ukusebenza kwe-silicone sealant, okanye iyenze ibe nzima.Kwiimeko ezinzima, ukusebenza kwenkalo ethile ye-silicone sealants iya kulahleka, kwaye imveliso iya kuchithwa.

Makhe sithethe ngezinye iingcebiso ze-silicone sealants zokugcina.

Kwindawo yobushushu obuphezulu, i-silicone sealant iya kukhawulezisa ukuguga, ivelise into "yokunciphisa", ikhawuleze ilahleko yezinye iipropathi, kwaye inciphise ubomi beshelufu.Ngoko ke, ubushushu bokugcina bunempembelelo enkulu kumgangatho we-silicone sealant, kwaye ubushushu bokugcina bufunekayo ukuba ungadluli i-27 ° C (80.6 ° F).

Kwindawo yobushushu obuphantsi, iqondo lobushushu eliphantsi kakhulu liya kubangela ukuba i-agent edibanisa umnqamlezo kunye ne-agent yokudibanisa kwiglue ye-silicone ikhazimle.Iikristale ziya kubangela ukubonakala kakubi kweglue kunye nezongezo zasekhaya ezingalinganiyo.Xa ukulinganisa, i-colloid inokunyangwa ekuhlaleni kodwa ayinyangeki ekuhlaleni.Ke ngoko, i-silicone sealant ecwebezelayo ayinakusetyenziswa.Ukuze kuthintelwe irabha ye-silicone ekukhanyeni, indawo yokugcina akufanele ibe ngaphantsi kwe -5 ° C (23℉).

Kwindawo enomswakama ophezulu, i-silicone sealant iyaqina xa idibana nomphunga wamanzi.Ubuninzi bomswakama ohambelanayo busendaweni yokugcina, ngokukhawuleza ukunyanga kwe-silicone sealant.Izitywina ezininzi ze-silicone zivelisa isixa esikhulu se-sealant eyomileyo kwiinyanga ezi-3-5 emva kokuveliswa, ehambelana ngokuthe ngqo nokufuma okuhambelana nendawo yokugcina iphezulu kakhulu. , kwaye kufaneleka ngakumbi ukufuna ukufuma okunxulumene nendawo yokugcina ukuba kube ≤70%.

Lilonke, iimveliso zerabha ye-silicone kufuneka zigcinwe kwindawo eyomileyo, enomoya, nepholileyo.Olona bushushu bokugcina buphakathi kwe -5 kunye ne 27°C(23--80.6℉), kwaye okona kufuma kokugcina ngu ≤70%.Iyakuphepha ukugcina kwiindawo ezinomoya, imvula, nokukhanya kwelanga.Ngaphantsi kweemeko eziqhelekileyo zokuthutha kunye nokugcinwa, ixesha lokugcina ubuncinane kwiinyanga ezi-6 ukususela kumhla wokuvelisa.

Ukuthintela ukuwohloka komgangatho weemveliso zerabha ye-silicone ngexesha lokugcinwa, indawo yokugcina impahla kufuneka ibekwe kwindawo epholileyo ngaphandle kokukhanya kwelanga.Kwakhona akunakwenzeka ukuba ukhethe iindawo eziphantsi ezixhomekeke ekuqokeleleni kwamanzi.Kwiindawo zokugcina iimpahla ezinobushushu obuphezulu, kufuneka senze umsebenzi omhle wokupholisa uphahla.Indawo yokugcina impahla enomaleko wokugquma ubushushu phezu kophahla yeyona nto ilungileyo, kwaye kufuneka ifakwe umoya kwangaxeshanye.Ukuba iimeko zivuma, indawo yokugcina impahla ixhotyiswe ngezifudumezi zomoya kunye nezithinteli manzi zokugcina indawo yokugcina impahla ikwiqondo lobushushu elingaguqukiyo kunye nokufuma ngexesha lasehlotyeni nakwixesha leemvula.

Ixesha lokuposa: Aug-23-2023